Improved print bed calibration

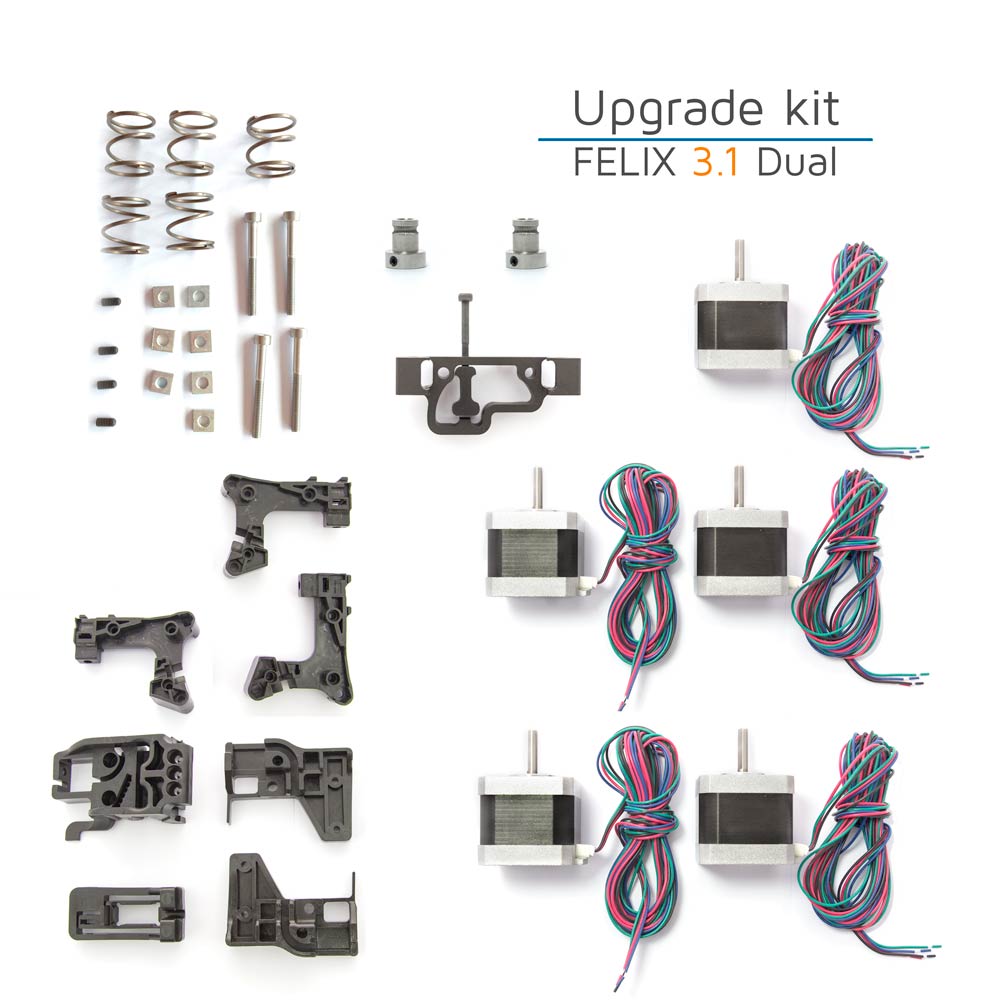

The Z-height calibration mechanism has been redesigned and improved in a way that the print bed keeps it’s calibration height over time. Recalibration of the z-height is reduced to a minimum. The curved washers underneath the heated bed are replaced by regular springs. This makes assembly easier and also adjustment of the height of the three points better controllable.

Extruder reliability improved

Improved filament intake

The upgrade contains a new extruder drive wheel. This features more durable material (stainless steel), sharpened teeth and a curved contact surface. This results in an incredible increase in filament grip compared to the previous brass wheel. Also the durability is improved, due to better material use. The curved contact face, not only improves grip, but also guides flexible filaments better into the hot-end, improving reliability reducing jams and improving robustness to varying filament diameter. This should make printing with clog-prone filaments like PVA and Flex easier.

New plastic extruder frame parts

The redesigned extruder assembly (the part that moves along the X axis) is more stiff than before. The new design's increased stiffness reduces the vibration experienced at the tip of the hot end, resulting in even higher print quality. The plastic parts of the extruder are molded with better tolerances and also slight improvements in the design. This make the parts easier to assemble.

Only for Dual: hot-ends calibration

The new extruder carriage allows for easy calibration of the individual hot-ends. With an Allen key (Hex key) (size 2.5) the right-side hot end can be positioned for perfect alignment with the left-side hot end. The new extruder assembly also allows the right-side hot-end to be stowed away to prevent it from colliding with printed parts when printing in single-head mode.

Better controllable filament pressure of extruder arm

By using carefully selected regular springs instead of curved washers you are able to better adjust the pressure exerted onto the filament to go into the hot-end. Also because the spring exert an optimal pressure onto the filament it improves print reliability.

Improved Y-axis accuracy

The slightly improved geometry of the y-axis belt mount parts make sure teh belt of the y-axis stays at the same height, improving better print tolerances in y-directon.

Click here to download the assembly manual for FELIX 3.0 to FELIX 3.1

| Printer Model | FELIX 3.0 |

|---|---|

| Shipment |  |